이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

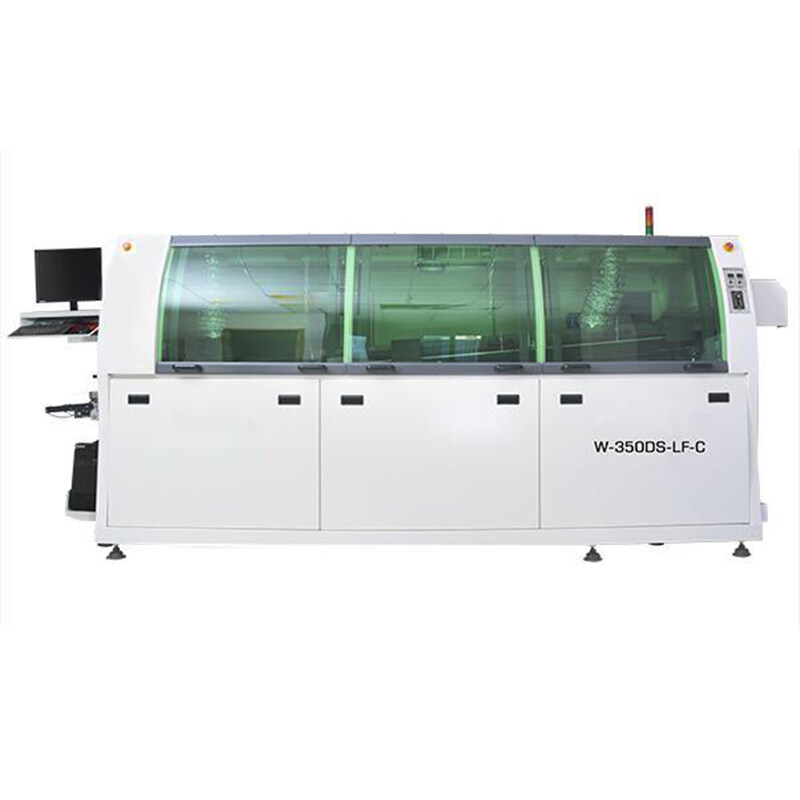

Double-Sided AOI Automatic Optical Inspection Machine

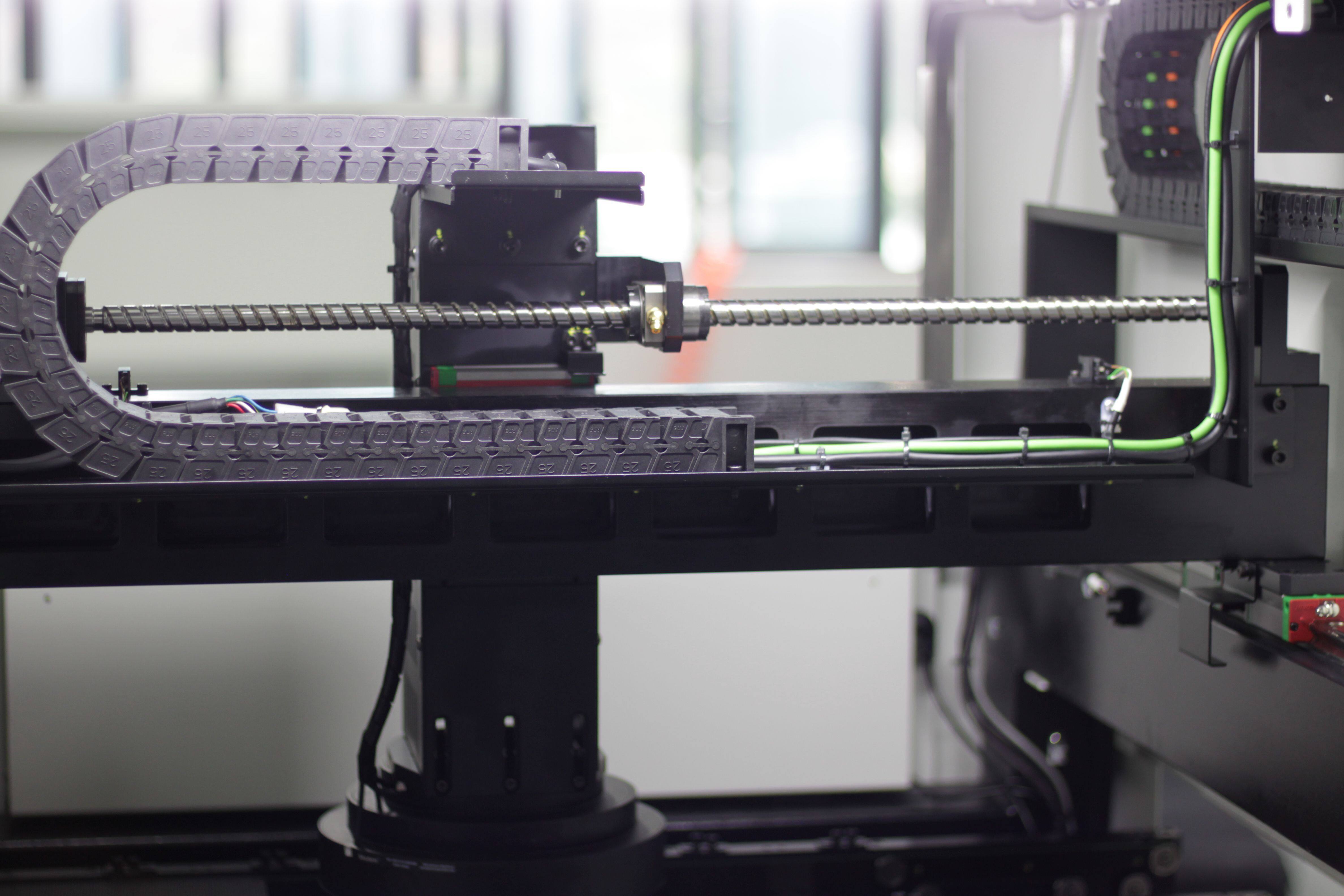

The Granite platform for SMT pre- and post-reflow inline inspection uses double-sided automatic AOI inspection equipment, which considerably enhances machine precision and stability. RGB+W LED lighting source that is programmable Telecentric lens that responds to high compression with low distortion and constant magnification.

Double-Sided AOI Automatic Optical Inspection Machine

A double-sided AOI machine is a specialized equipment used in electronics manufacturing to automatically inspect both sides of printed circuit boards (PCBs) for defects and inconsistencies. Here's some information about a double-sided AOI automatic optical inspection machine:

Function and Purpose:

- Inspection of both sides: The primary function of a double-sided AOI machine is to inspect both the top and bottom sides of PCBs for defects, errors, or anomalies that may affect the functionality or reliability of the assembled board.

- Comprehensive inspection: These machines utilize advanced imaging systems, including cameras and image processing algorithms, to capture detailed images of both sides of the PCB and analyze them for various types of defects simultaneously.

- Detection and classification: AOI machines can detect defects such as missing components, misaligned components, soldering issues (e.g., bridging, insufficient solder, solder shorts), incorrect polarity, tombstoning, and other manufacturing defects on both sides of the PCB.

- Quality control: By identifying and flagging defective PCBs, double-sided AOI machines play a crucial role in quality control, ensuring that only high-quality and defect-free boards proceed to the next stage of the production process.

Features of a Double-Sided AOI Automatic Optical Inspection Machine:

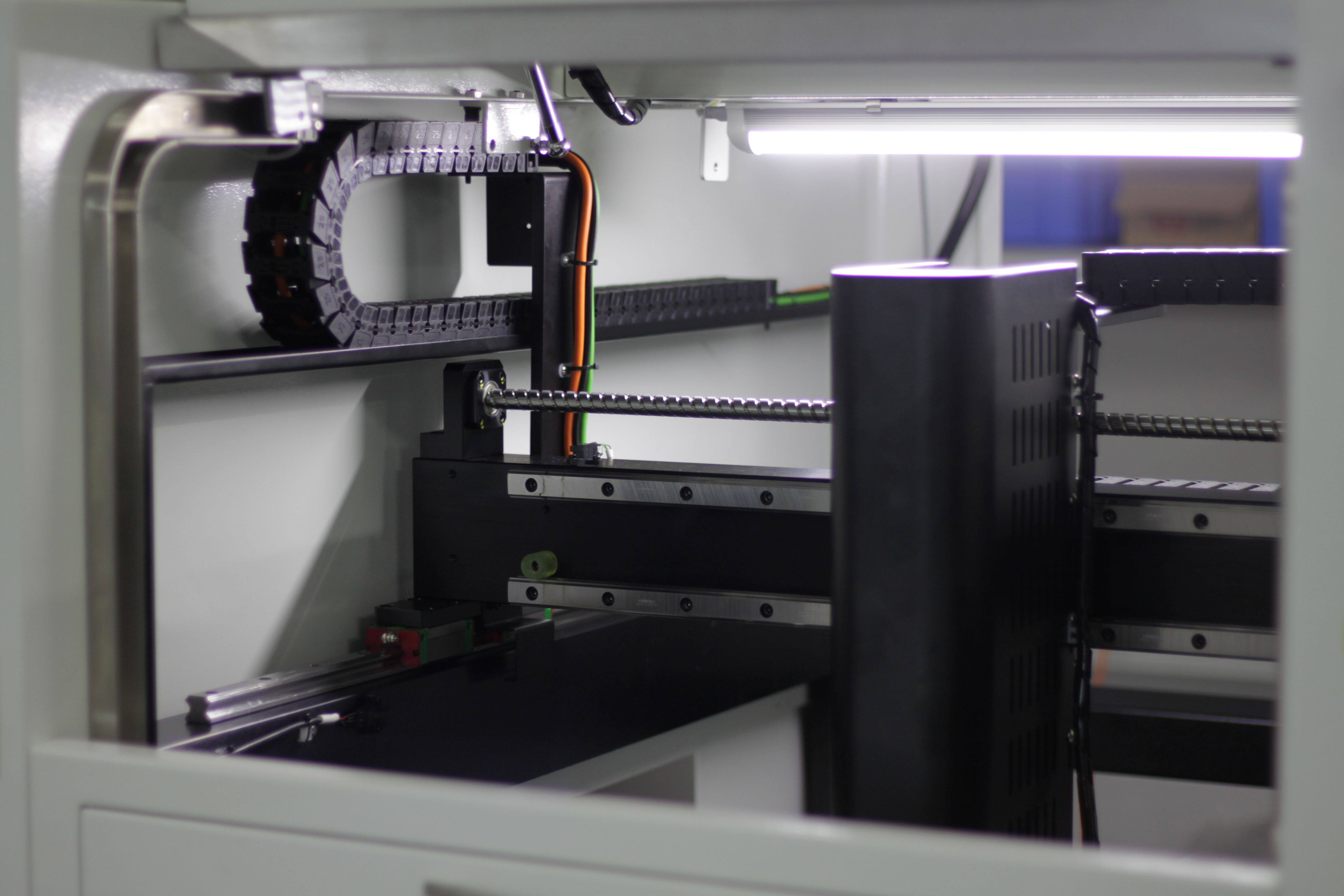

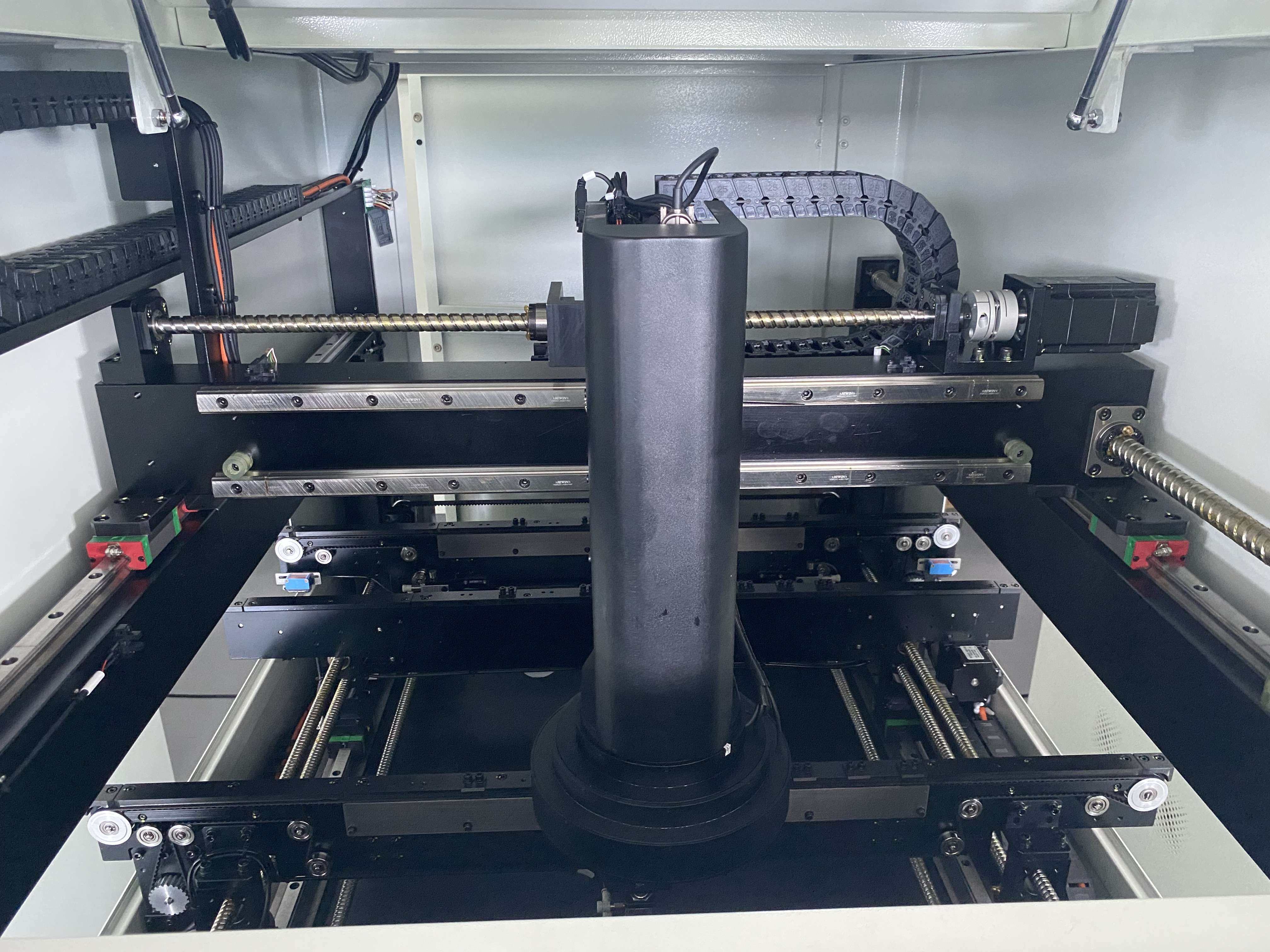

- Dual-sided imaging system: The AOI machine is equipped with multiple cameras or mirror systems to capture images of both the top and bottom sides of the PCB simultaneously.

- Lighting system: Specialized lighting techniques, angles, and wavelengths are used to enhance the visibility of features and defects on both sides of the PCB.

- Image processing algorithms: Advanced algorithms analyze the captured images, comparing them to reference images or predefined criteria to identify and classify defects accurately on both sides of the PCB.

- Database and reporting: AOI machines often include a database to store inspection results and generate comprehensive reports, providing traceability and facilitating further analysis or corrective actions.

Advantages of using a Double-Sided AOI Automatic Optical Inspection Machine:

- Comprehensive inspection: Simultaneous inspection of both sides ensures that defects on either side of the PCB are detected, reducing the risk of overlooking critical issues.

- Increased efficiency: The ability to inspect both sides in a single pass reduces cycle times and increases throughput, improving overall production efficiency.

- Accuracy and consistency: Automated inspections ensure consistent and objective results, reducing the risk of human error and subjective judgment in defect detection.

- Cost savings: Early detection of defects allows for timely corrective actions, reducing scrap, rework, and potential customer returns or field failures.

Considerations when using a Double-Sided AOI Automatic Optical Inspection Machine:

- Programming and setup: Proper programming and calibration are crucial to ensure accurate defect detection and minimize false positives or negatives on both sides of the PCB.

- Integration: The AOI machine should be seamlessly integrated into the SMT assembly line, allowing for efficient transfer and inspection of PCBs without causing bottlenecks or delays.

- Maintenance and calibration: Regular maintenance, cleaning, and calibration of the AOI machine are necessary to maintain optimal performance and accuracy on both sides of the PCB.

Double-sided AOI automatic optical inspection machine offers significant advantages in terms of comprehensive inspection, efficiency, and quality control. By automating the inspection process for both sides of the PCB, these machines contribute to improved product quality, reduced manufacturing costs, and enhanced customer satisfaction.

TECHNICAL PARAMETER - AOI Automatic Inspection Machine Equipment

|

Model |

HCT-AT510 |

|

|

PCB Specifications |

Max. PCB size (X x Y) |

510mm x 460mm |

|

Min. PCB size (Y x X) |

50mm x 50mm |

|

|

PCB Thickness |

0.6mm~6mm |

|

|

Board Edge Gap |

3mm |

|

|

Max. Bottom Gap |

25mm~80 mm Adjustable |

|

|

Max. Top Gap |

25mm~85 mm Adjustable |

|

|

PCB Weight |

Belt Drive:≤10Kg;ChainSprocketDrive:≤30Kg |

|

|

|

After Reflow-soldering |

Chip:wrong parts, missing parts, polarity, offset, tombstone, reverse, damaged, IC bent feet, foreign objects Tin Soldering: No tin, less tin, more tin, bridge, dummy solder, solder ball |

|

|

AfterWave-soldering |

Chip:wrong parts, missing parts, polarity, offset, tombstone, reverse, damaged, IC bent feet, foreign objects |

|

DIP:Insert pin, no tin, less tin, more tin, hole, dummy solder, solder ball |

||

|

Components Range |

Chip:03015 and above;LSI:0.3mm pitch and above;Others:Special shaped component |

|

|

Inspection Speed |

200~250ms/Fov |

|

|

MovementMechanism

|

X/Y Drive |

AC Servo Motor |

|

TrackWidthAdjustmentMethod |

Automatic adjustment +Manual adjustment |

|

|

Transmission Speed |

1500mm/s(Max) |

|

|

Transmission Height |

740mm±30mm/900mm±30mm (Optional) |

|

|

Transmission Direction |

L – R、R – L、L – L、R – R (Pre-factory setting) |

|

|

Transmission Mode |

Belt drive(Standard); ChainSprocketDrive is optional |

|

|

Fixed Rail |

Front rail is fixed |

|

|

PCB Clamping Method |

Edge locking + base plate clamping |

|

|

ImageParameters |

Camera |

Up Camera:12MP Industrial Camera (USB3.0 high-speed interface) Down Camera:5MP Industrial Camera GigE Vision (Gigabit network interface) |

|

Resolution |

Up Camera: 10μm Down Camera:5MP:15μm(60mm*49mm) |

|

|

Lens |

Telecentric Lenses |

|

|

Lighting System |

Multi-angle surrounding 4-color ring programmable LED light source (RGBW) |

|

|

Hardware Configure |

Operation System |

Windows 10 Professional Edition 64-bit |

|

CommunicationMode |

Ethernet,SMEMA |

|

|

Power Supply |

AC220V±10%,50/60HZ,1.8kVA |

|

|

Air Supply |

4~6Kg/cm2 |

|

|

Dimensions |

L(1030mm)×W(1420mm)×H(1550mm)(without alarm lamp height) |

|

|

Weight |

Approx. 900kg |

|

|

TemperatureResistance |

Belt drive:≤60℃;Chain Sprocket Drive:≤150℃ |

|

|

AbsoluteHumidity |

25~80%RH4 |

|

The Double-sided Automatic AOI Inspection Equipment is for SMT pre-reflow, post-reflow inline inspection Granite platform, greatly improving machine precision and stability Programmable RGB+W LED lighting source Telecentric lens with constant magnification and low distortion response to high compone.

Product Features - AOI Automatic Inspection Machine Equipment

Technical Advantages - AOI Automatic Inspection Machine Equipment

- FOV assisted positioning technology + component pad positioning

FOV-assisted positioning can accurately locate small components and perform solder joint inspection, and can effectively detect small components and solder joints near high components;

Component-level pad positioning can effectively solve the false alarms and false alarms caused by board bending for flexible boards. FOV positioning is used for non-flexible boards, which can ignore the interference of screen printing and printed lines on the board, and easily realize pad positioning and packaging. detection accuracy;

- Based on pad positioning technology. Test data is directly connected to API standards

It is not acceptable for IPC-A-610-G Class 3 component terminations to extend beyond the land by more than 25% of the termination width.

- DIP Solder Joint Dedicated Algorithm

On the basis of precise positioning, it is equipped with special algorithms for hand-plug and machine-plug DIP solder joint inspection. Effective detection of solder joint virtual welding.

Product Display - AOI Automatic Inspection Machine Equipment